Formed by a combination of digitally controlled and manual processes, this work can decorate a wall as well as a table. A CNC router cuts the pattern I designed, guiding the manual deformation of the aluminium composite material into a 3d form. This material is lightweight, durable and colourfast, all qualities that make them ideal for creating lasting individually designed works.

Posts Tagged 'kunst'

Curve/Curve gold, new folded form

Published 19/11/2012 art , craft , design , designer/maker , digital fabrication , objects , technology , Uncategorized Leave a CommentTags: aluminium, art, cnc, craft, design, fold, folded, gilbert, kunst, kunsthandwerk, object, riedelbauch, router

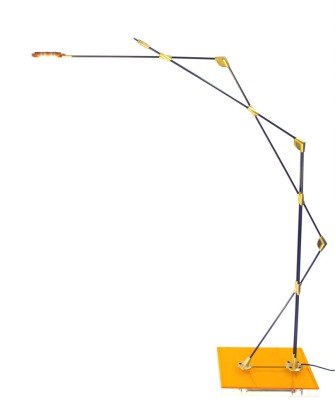

Knicks LED light, use of digital fabrication for design prototyping

Published 29/10/2012 Uncategorized Leave a CommentTags: acrylic, art, craft, design, gilbert, gold, handwerk, kunst, lampe, laser, led, licht, light, ponoko, prototyping, rapid, riedelbauch

This light was in the making for a long time and is now finally completed. See earlier post. Its design includes several digital fabrication processes like laser cutting (acrylic and brass) and rapid prototyping (gold-plated stainless steel) using Ponoko‘s distributed manufacturing system. All metal surfaces are gold plated taking advantage of Ponoko’s US based production hub which offers rapid prototyping directly into metal.

Its dimensions are: 600 x 150 x 710 mm and the light head holds four 1watt LED’s.

ur QR

Published 15/07/2012 art , craft , design , Links , research , software , technology , Uncategorized , web 2 Leave a CommentTags: art, craft, design, gilbert, gilbertriedelbauch, kunst, kunsthandwerk, qr, qr code, riedelbauch

I am getting quite fond of QR (quick reference) codes. These strange square pattern link the ‘real’ world to information or places in cyperspace. You can ‘read’ them with your smart phone – I use the iPhone app QRReader – or create them with their phone or on a website like qrstuff. Such a code can assist with promoting professional practice and can find its way on your business and invitation cards as well as your email signature block.

Here is a QR code linking straight to my new website.

(Either scan it with a QR reader or just click on it)

Unexpected Pleasures Jewellery Exhibition

Published 03/05/2012 art , craft , design , digital fabrication , exhibition , FDM , objects 2 CommentsTags: art, contemporary, craft, design, design museum london, gilbert, jewellery, kunst, kunsthandwerk, ngv, rapid prototyping, riedelbauch, schmuck, Silber, silver, unexpected pleasures

With over 200 objects from 26 countries on display Unexpected Pleasures represents a significant global survey of contemporary jewellery.

The ring by Camilla Prasch features on the cover of the catalogue and the NGV invite.

First on show at the National Gallery of Victoria, Melbourne, 20 April – 26 August 2012, this exhibition will also tour to the Design Museum in London, 5 Dec 2012 – 3 Mar 2013. Melbourne based designer and maker Dr. Susan Cohn (interview with The Age) has curated this exhibition for the Design Museum and is also co-author of the substantial catalogue documenting this event as well contributing to the discussion about contemporary design and making.

I find interesting that 2/3 of the makers who have been selected to contribute works come from only four countries: Australia, Germany, The Netherlands and the UK. Which seems to make these the centre of global contemporary jewellery.

The following piece of mine was selected for this exhibition:

This object has its origin in mathematics. An equation describing a ‘minimal surface’, has been altered to explore its aesthetic properties. This form was built using ‘fused deposition manufacturing (FDM)’ a rapid prototyping process. This process generates a rough machine surface creating an intriguing surface pattern. You can find more information about this body of work by following this link.

Here is also a link to a more detailed review and many more images of works as well as the show in the NGV by Art Blart.

A post about a post

Published 22/11/2010 art , exhibition , teaching learning , web 2 Leave a CommentTags: art, David Hockney, digital, gilbert riedelbauch, Hockney, iPad, kunst

What goes round, comes round. I was surprised to find my post ‘True digital art on iPad by David Hockney‘ almost word for word as well as image for image re-posted and littered with advertising by ‘theproductjudge’. As this post was intended as a thank-you to David Hockney’s for his generosity, I am frustrated by this syndication, code for rip-off. Frustratingly they even ripped-off my title and achieved swiftly a much higher Google ranking.

However, my blog stats suddenly increased as one of my images showing David Hockney’s drawings on iPads has gone up in Google’s ranking – number 4 if one searched ‘David Hockney iPad’ – due to this appropriation.

Similar to this but legit: Martyn Gayford wrote online about Hockney’s current exhibition of iPad drawings in Paris, days later this text was printed – ink on paper – in the ‘Canberra Times’ including the image of me with the iPads taken at an earlier event at ANU School of Art.

So, what ever is available can reappear in many forms. I just would have liked to been asked before someone uses my words and images (intellectual property) and tries to make a commercial gain.

True digital art on iPad by David Hockney

Published 09/10/2010 art , teaching learning , technology , web 2 6 CommentsTags: art, David Hockney, digital, drawing, Hockney, iPad, kunst, sketch, technology

This post is to thank David Hockney for making available two of his recent iPad drawings to my teaching program at the School of Art at the Australian National University.

We celebrated these impressive drawings, which are in every sense true digital art works, as part of Core Computer Studies lecture to our 1st year students and guests. I decided to display these works on two Apple iPads, the very platform/media they were created on.

David Hockney drew them during his stay at Glyndebourne, a 700-year old country house and opera house in East Sussex, England. There he recreated the stage-set for the opera ‘The Rake’s Progress’ by Stravinsky . Looking closely at these drawings one gets a sense of this location. The drawings titled: ‘iPad 6 8 2010’ & ‘iPad 7 8 2010’ were sent as email attachments on 21 August 2010.

I like to thank Martin Gayford, critic for Bloomberg News, for kindly forwarding my emails to David Hockney. I also like to thank Tristan Peemoeller from MAC1, Greg Aldridge and Barbara McConchie for their support, to make the presentation of these works possible.

This event was picked up by the news, please read more here.

Light objects for Art School Library, design

Published 15/05/2010 craft , design , digital fabrication , FDM , lamp , lampe , licht , lights , objects , rapid prototyping , technology 2 CommentsTags: art, craft, design, desk light, kunst, lamp, led, leds, light, lights, rapid prototyping, technology

In December 2009 I installed two light objects in the library at the ANU School of Art. Please find a post about the making of these lights here.

These two lights provide four ‘highlighted’ spots for reading or lab top use within the reading pit. The design intent was to connect the space inside the glass walls of the reading pit with the surrounding architecture. The objects themselves should have a mechanical but yet organic feel to them. I used the two columns on either side of the reading pit as anchor points from which the lights reach over the seating area in a ‘branch and twig’ fashion. All brass parts of these lights – being cylinders of sorts – referring to these columns. The lights are lightly strapped to the columns highlighting their light weight construction. The colours have been limited to Brass (gold), black and red.

The lights are made of aluminium (powder coated black), brass, carbon fiber tubes and LEDs.

The designs on the glass panels and on the fabric on the cushions are by Annie Trevillian. Many thanks also to Irene Hansen (head librarian) and Murray Napier for their support of this project.

web 2 and distributed manufacturing for designer – maker

Published 17/06/2009 art , craft , FDM , lights , rapid prototyping , research , technology , web 2 1 CommentTags: art, craft, design, desk light, digital, gilbert riedelbauch, highlights, kunst, lamp, light, lights, rapid prototyping, research, technology

Based on web 2 technologies, a growing variety of production processes are becoming easily accessible for anyone.

An online interface makes highly specialized technologies available. Once you setup your account, payment and shipping options are selected you can start producing and in some cases have access to a network of like-minded users or potential customers.

Companies like Ponoko (laser cutting and engraving), RedEye (Rapid Prototyping) and blurb (bookmaking) can successfully contribute to a designer/maker practice. A competent level of computer skills are required to address these services to achieve the best outcome. For waterjet or laser cutting, which are essentially two dimensional processes, of flat or sheet materials the mastery of a vector-based graphics program like Adobe Illustrator is essential. To use the RedEye ‘factory of the future’ one needs to generate a .stl file of a virtual 3D object that had been modeled in a CAD program.

The underlying specialized technology, for a long time the domain of the manufacturing industry, is expensive and usually out of reach of a single craft practitioner. If acquired, such equipment would ‘tie’ the individual maker to this technology for a long time and introducing a high level of risk to their business. Not to mention high running cost and that these digitally based technologies become obsolete within a few years.

I have used several of these processes while designing and making the ‘desk light‘, it has a waterjet cut stainless steel plate, a lasercut lamp shade (Ponoko) and Rapid Prototyping parts. Using these technologies has led the design process to new solutions and made the making of this light relatively easy.